Goods Receiving Area Meaning Every item that arrives represents a commitment a promise to deliver quality and reliability to the end customer The receiving process therefore is not just about handling

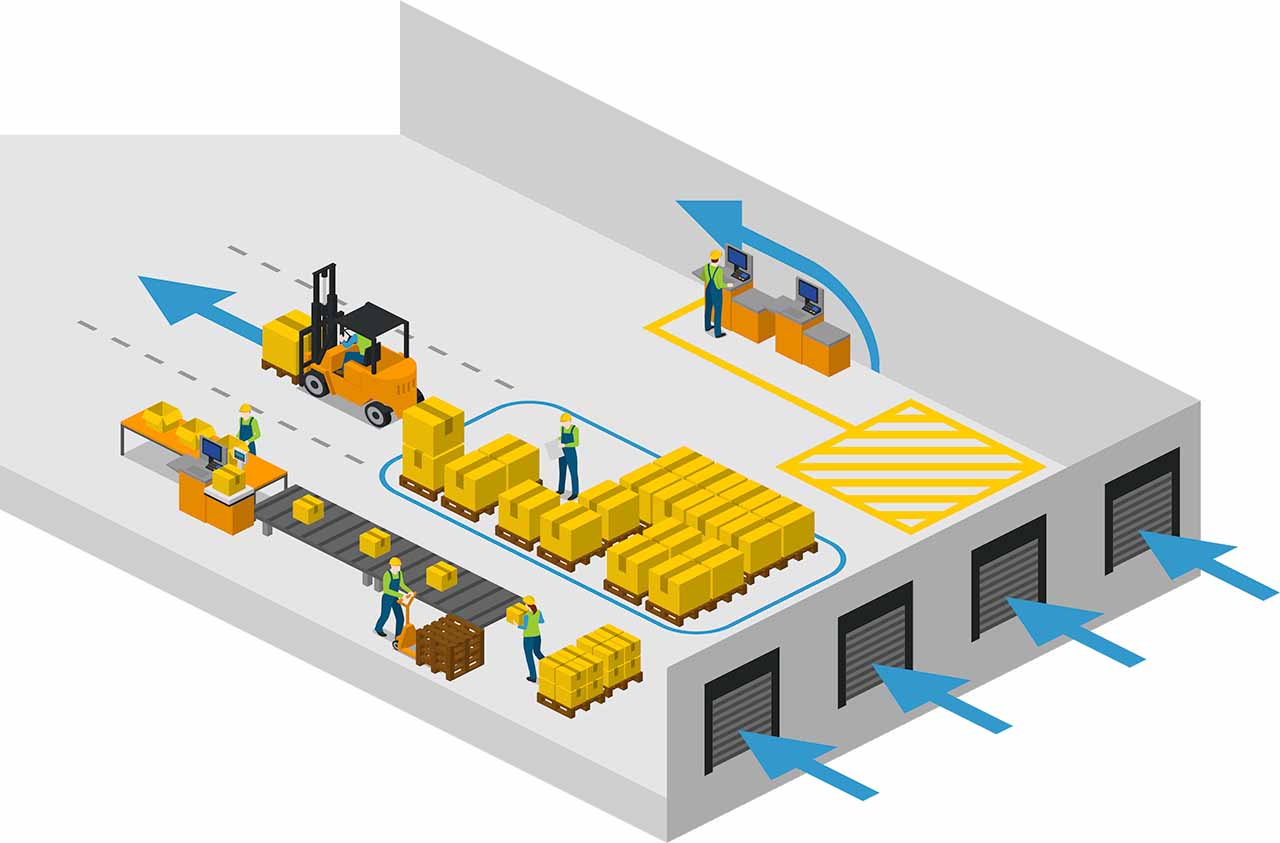

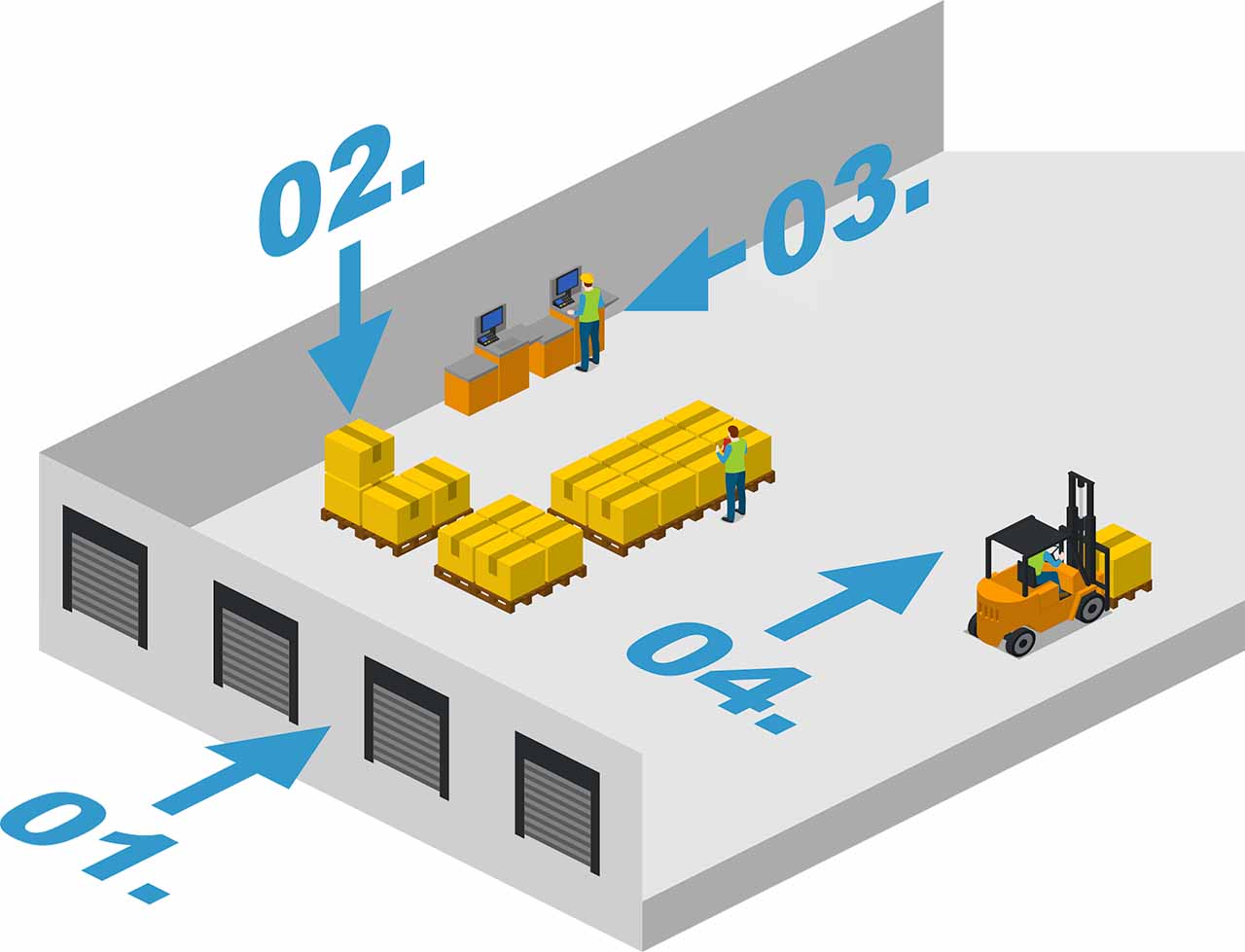

What is goods receiving Goods receiving is the function of checking items delivered to the business either coming in as new stock or as supplies This includes What is the receiving area of a warehouse The receiving area of a warehouse is the designated space where incoming shipments are unloaded inspected and verified before being sorted and stored in the warehouse This

Goods Receiving Area Meaning

Goods Receiving Area Meaning

https://i.ytimg.com/vi/qlmTiQN6ikg/maxresdefault.jpg

Container Unloading

https://goldenstatemh.com/wp-content/uploads/2018/07/container_unloading.jpg

The Receiving Department Process Driven Warehouse

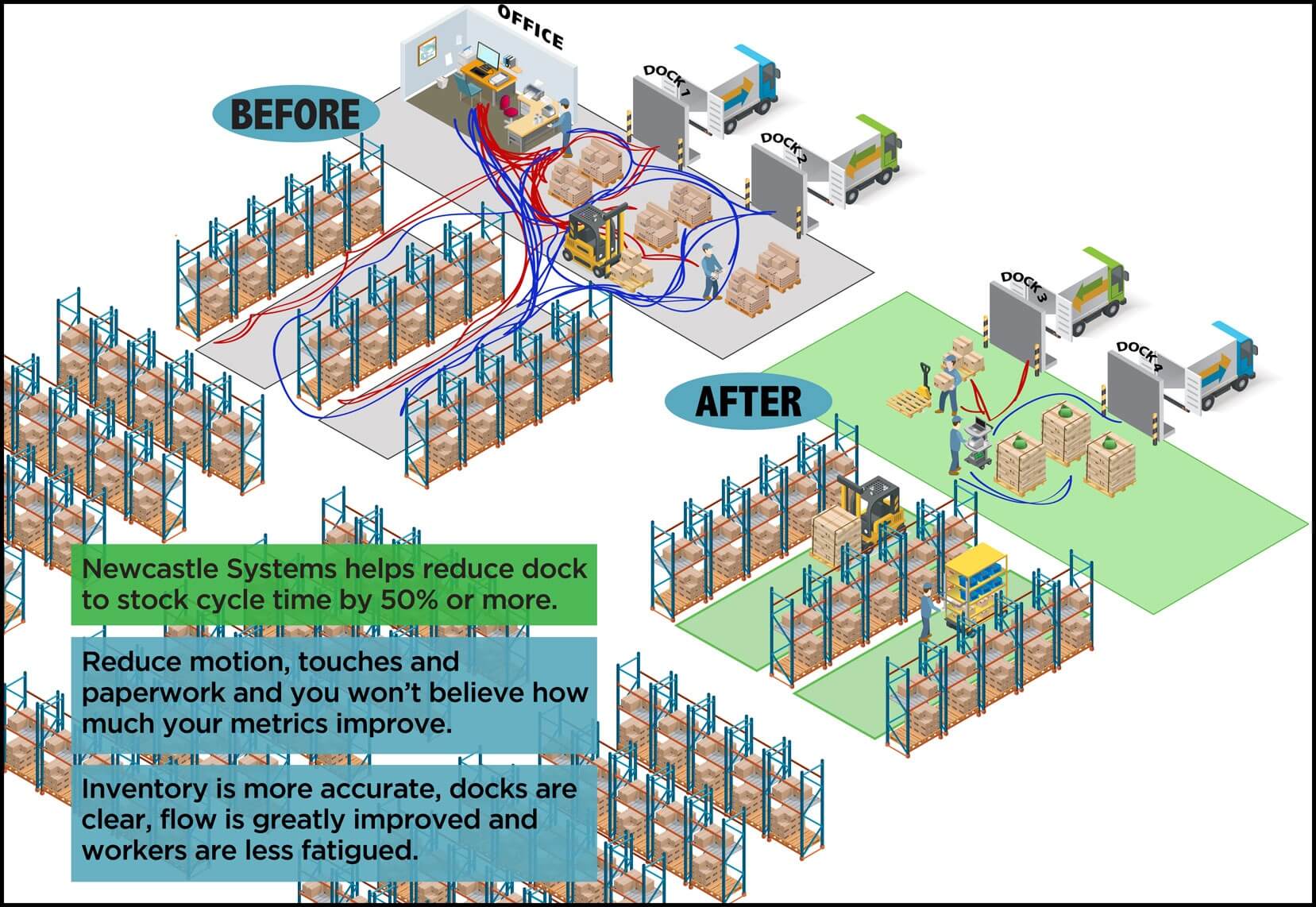

https://www.newcastlesys.com/hs-fs/hubfs/images/Warehouse-Dock-to-Stock-NoLogojpg.jpg?width=1998&name=Warehouse-Dock-to-Stock-NoLogojpg.jpg

The receiving area in your warehouse is the place where your new items go for sorting and quality control It needs to be sizable enough to accommodate numerous deliveries and allow for sorting You ll also be tasked Goods receipt is one of the most important in warehouse operations as it is what kicks off the flow of materials What phases does the process involve What strategies can I apply

Optimizing your warehouse receiving area layout means arranging your inventory staging area processing zone and put away lanes around your warehouse docking A well thought out receiving area layout isn t just about arranging shelves and equipment it s a strategic approach to managing the flow of items from the moment they arrive at your facility Imagine a puzzle where each

More picture related to Goods Receiving Area Meaning

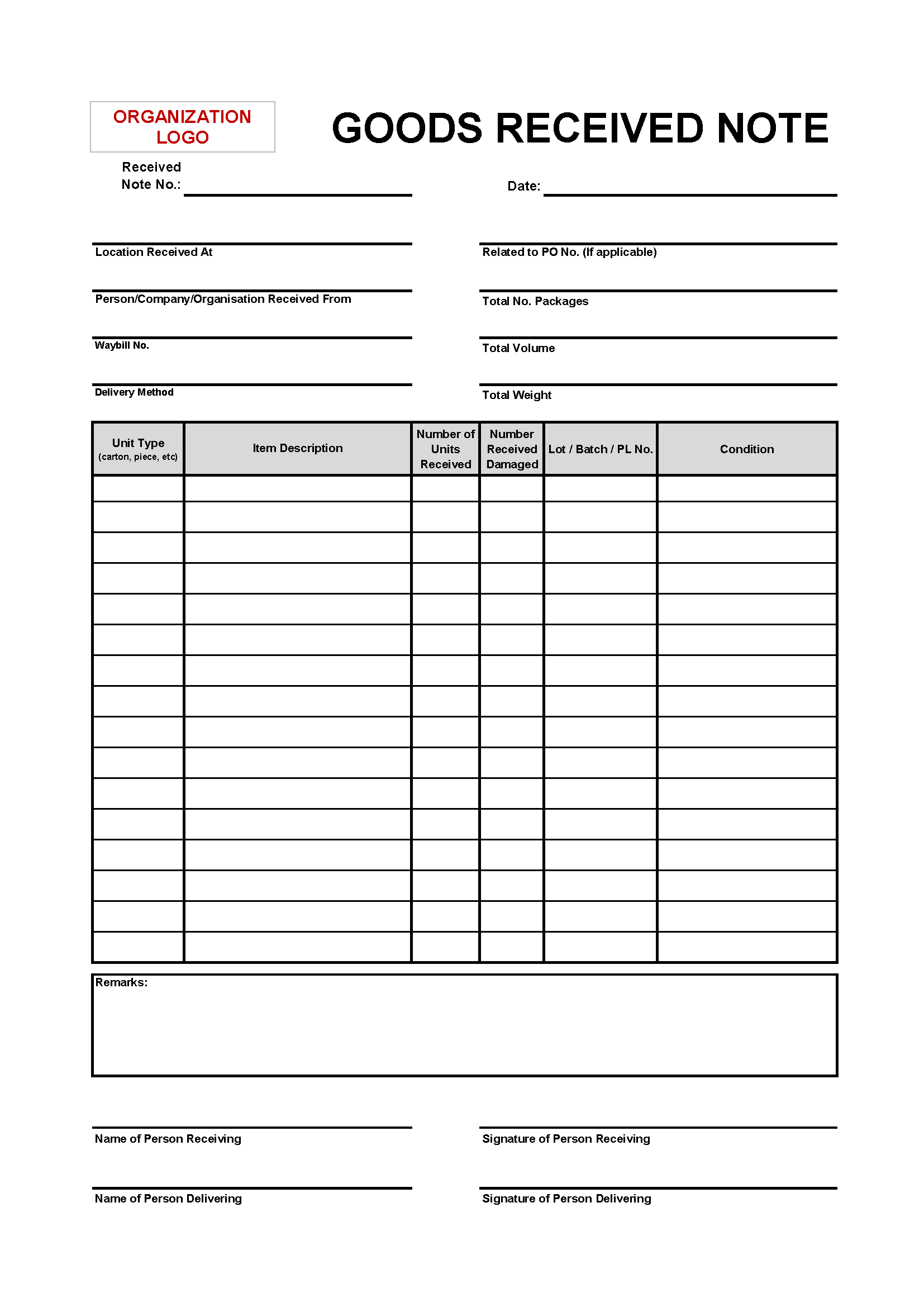

Warehousing Documentation Logistics Operational Guide

https://log.logcluster.org/sites/default/files/2023-03/Goods Received.png

Receiving CaptureTech

https://www.capturetech.com/wp-content/uploads/2022/11/goederenontvangst.png

Goods Receiving Inspecting Incoming Stock

https://saferstoragesystems.com.au/wp-content/uploads/2016/04/Checking-Goods-Received.jpg

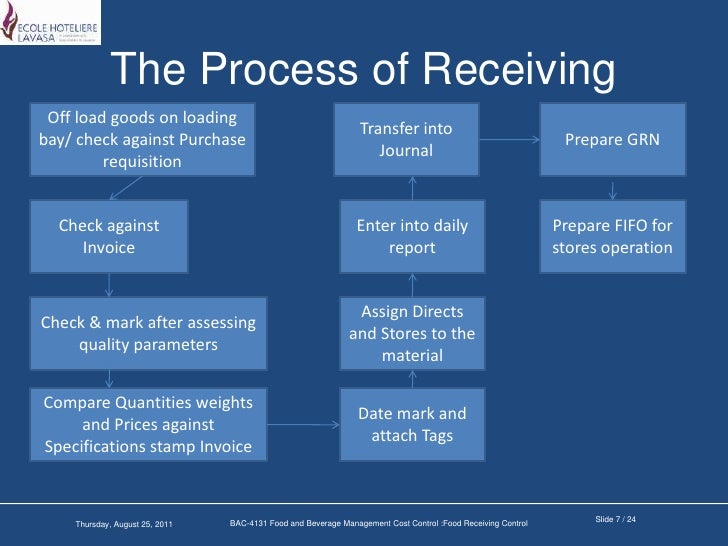

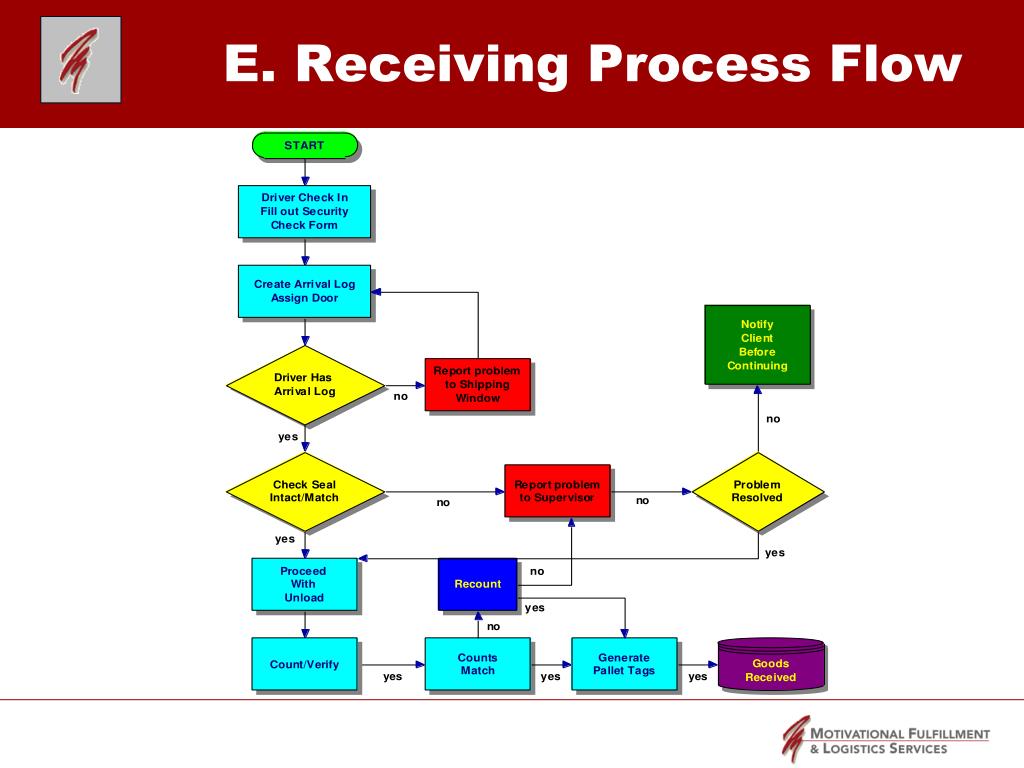

Receive and process incoming goods stock receiving area The first step in the stock control process is the receiving of goods which are delivered to the store This procedure is an extremely important process as Warehouse receiving is the critical first step in the supply chain process It involves the receipt of goods from suppliers and their preparation for storage or further distribution This stage sets

An efficient receiving area has many benefits including improved accuracy in inventory tracking reduced labor costs associated with manual handling of goods and Receiving area is one of the zones in magazine dedicated to technical and operational activities relating to the receiving of materials and goods It is the first part of the magazine The goods

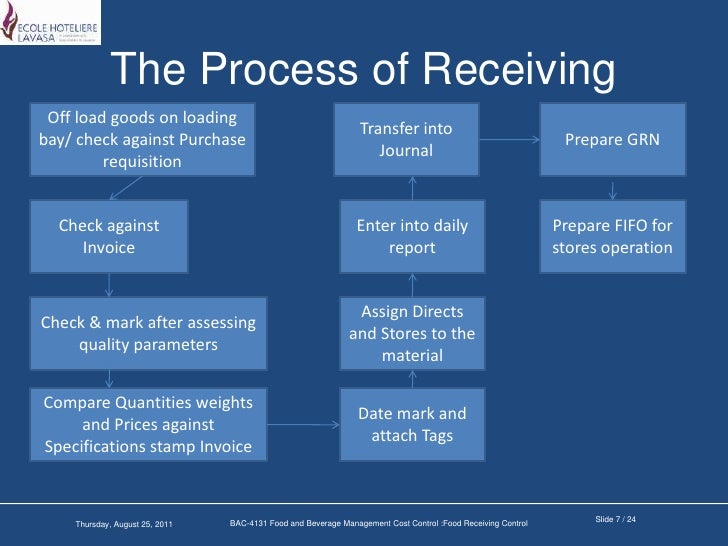

Food Receiving Control

https://image.slidesharecdn.com/foodreceivingcontrol-110826001111-phpapp01/95/food-receiving-control-7-728.jpg?cb=1314317569

Goods Receiving Inspecting Incoming Stock

https://www.saferstoragesystems.com.au/wp-content/uploads/2016/04/Goods-Receiving-Process.png

https://www.cadretech.com › blog › warehouse-receiving-process

Every item that arrives represents a commitment a promise to deliver quality and reliability to the end customer The receiving process therefore is not just about handling

https://saferstoragesystems.com.au › receiving-and-inspecting-goods

What is goods receiving Goods receiving is the function of checking items delivered to the business either coming in as new stock or as supplies This includes

Receiving Process Map

Food Receiving Control

Receive Package Line Icon 7637156 Vector Art At Vecteezy

Interlake Mecalux Bobo

Receive Package Icon

Receiving Of Goods Concept Icon Stock Vector 2853319 Crushpixel

Receiving Of Goods Concept Icon Stock Vector 2853319 Crushpixel

Warehouse Receiving Process In

Warehouse Receiving Process In

Warehouse Receiving Process In

Goods Receiving Area Meaning - In the receiving area incoming goods and materials are normally unpacked checked for quantity accuracy and product damage repackaged organized into a storable format where required